Once in a while we are startled by the emergence of a new disease that threatens our crops. In order to prevent diseases and pests in general, or even a new disease, from entering the greenhouse from outside, strict hygiene measures are necessary. In this article several sources of infection will be explained.

In the cultivation of Phalaenopsis and Anthurium there are a number of diseases for which a high level of hygiene is of great importance for prevention. For Phalaenopsis, the main ones are the bacteria Acidovorax (Pseudomonas), Erwinia and the fungus Fusarium. These three diseases are responsible for more than 90% of the total loss in Phalaenopsis cultivation. For the cultivation of Anthurium, the bacterium Xanthomonas is the main reason for maintaining good hygiene. Last year, the bacterium Ralstonia solanacearum joined the list.

People

People in the greenhouse are the most important disseminators of fungi and bacteria. Through clothes, shoes and hands many pathogens are introduced and spread unnoticed in the greenhouse. Reducing this as much as possible is no superfluous luxury. This can be achieved by wearing clean (over)shoes and an overcoat or overalls when entering the greenhouse. Hands should be disinfected with a disinfecting gel at the entrance. Washing your hands with soap and water is also very effective.

Insects

Some insects also spread diseases. For example, it is known that certain thrips spread viruses. In Phalaenopsis cultivation the moss mite is notorious for spreading Acidovorax (Pseudomonas). By pricking the leaves, the infected plant sap can be spread from plant to plant. Beside the fact that these insects cause damage by sucking, the spread of diseases is also an important reason to keep them as far as possible from the door and to control them if necessary.

Plant material

Disease (and pests) can also enter the greenhouse with young plant material. A proper entrance control is indispensable. Make sure that (young) plant material is free of diseases when it enters the company.

Water

Splashing water is an important diffuser of bacteria and fungi. Traces present in the air are rained down during irrigation and end up on the crop. In addition, just a drop can also spread an infection from one plant to another. This can be avoided by adding a product to the water that kills the bacteria. In practice, this is achieved by chlorine dioxide (ClO2) or hydrogen peroxide (H2O2) or ionization of copper (Cu2+). The bacteria present in the water or on the plants are destroyed, as a result of which the spread by splashing is largely prevented. However, this method of disinfection cannot be used as a control.

Hygiene protocol

In order to increase hygiene in a nursery to a higher level, it is advisable to consider all the facts. Take into account the following elements:

- Who enters the greenhouse?

- What are the walking lines in the greenhouse?

- Where are the diseased or suspicious plants in the greenhouse?

- Where are my oldest plants situated?

- What enters the greenhouse as ‘foreign’ plant material?

Partly on the basis of the answers to the above questions, you can then make a plan to reduce the risks of infection to a minimum.

General (basic) measures

A number of measures can and must always be taken. Start by limiting the movements of people around the crop (mostly staff members).

- Restrict these movements to those that are strictly necessary for disease and infestation control and determining irrigation times.

- People coming from outside should always wear company clothes and shoes. In practice, this means wearing an overall and overshoes over your own clothes.

- Hands should always be disinfected or washed when entering the greenhouse and contact with the plants should be avoided.

Disinfection of hands and shoes

For the disinfection of hands, for example, it is important to know that disinfectants will be ineffective if the material to be disinfected is too dirty. In this case, the disinfectant cannot penetrate sufficiently because of the dirt. Wash your hands and make your shoes mud-free, if necessary, before disinfecting them. Staff are advised to use (company) work shoes or boots in the company. This is also recommended for visitors. By cleaning the shoes first, the disinfectant stays active for longer in the disinfection mats or tubs. It is important to first remove any organic material from machines and knives.

Disinfectants

In order to choose the most suitable disinfectant, it is important to determine for which disease it has to be effective. It should also be stipulated whether it is safe for the staff and whether there is sufficient time for the product to disinfect.

Plant resistance and disease pressure

A healthy plant will get diseased less easily than a weak plant. In addition, a higher disease pressure will also increase the risk of infestation. Stress factors in the cultivation, like a very high or low greenhouse temperature, also reduce the resistance of the plant and make it extra sensitive. In such a situation, you can decide to reduce the disease pressure as a preventive measure. This can be achieved by using a chemical agent, but there is also a wider choice of biological products and plant invigorators.

Barrier method

Hygiene measures can be divided in two parts:

- Hygiene from outside to inside the greenhouse

- Hygiene in the greenhouse

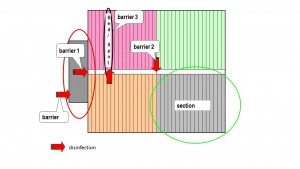

With such a subdivision you end up with the ‘barrier method’, according to which the greenhouse or a part of the greenhouse is divided into a smaller area or several smaller areas. The line between these areas is called a barrier. Barriers reduce the risk of infection in the company considerably. The main goal of the first barrier is to ensure that the fungus or bacterium is kept away from the greenhouse. The following barriers can be used to reduce the spread of fungi within the company. These barriers can be situated in different sections or even a barrier per bed or table.

What does the creation of barriers imply?

Barriers are established from the inside to the outside, or from clean to dirty. As a rule, you should always work from clean to dirty. It should be determined in advance, for instance, whether plant material may enter the greenhouse or a specific section. It may also imply a fixed working direction. When you work from young to older plant material and/or from disease-free to infected plants, you should strive to prevent healthy plant material getting infected by diseased plants. Another option is to work in the sections with infected plants or the oldest plants at the end of the week. By starting at the beginning of the week with clean clothes/machines, further spread can be reduced. In the cultivation of cut Anthurium, you can decide to work with a separate knife for each barrier. The advantage of these last two choices is that more time is spent on the disinfection of knives and machines, which clearly reinforces the effect. Sometimes it is possible to work within a few barriers with several people per barrier.

When you come into contact with plant sap in the course of sampling or controlling the plants and you are working across several barriers, then opt for working with plastic gloves and change these between the barriers.

It is advisable to make barriers as visible as possible by indicating with posters where a barrier starts and ends and which measures are expected. Between each barrier it has to be clear to everybody which hygiene measures are compulsory. Control over potential transfer is very important. The barriers can be indicated by foil, screens or a partition wall. You can establish the policy that everybody who has worked in the cooling or finishing phase should disinfect their hands before going on to work in the growing phase.

First barrier

The first barrier is the most important one: it aims at keeping the fungi and bacteria away from the greenhouse. The best place for this barrier is the entrance to the greenhouse. During the break there might have been contact with fungi and bacteria and in the packaging area pathogens may be present. A first barrier at the entrance of the company can do no harm, of course. It reduces the disease pressure in the warehouse and/or in the office as well as the pressure on the next barrier.

Second barrier

The greenhouse often consists of several sections. These sections are easy to protect from each other. Each door to the next greenhouse implies crossing the following barrier, the second barrier. At the second barrier a distinction is usually made between young and old material, between different cultivation phases like growing, cooling and finishing, or between diseased and infected plant material. By using closures between these sections, everybody can see clearly where hygiene measures are applied.

Third barrier

After crossing the second barrier, it is possible to include a third one. This is often the case for plants which may be infected or a place where loss has occurred. It can be applied for each bed, table or an old source where diseased plants have been eliminated. Mark such a place or protect it with a foil. Work as much as possible away from the source and leave the source until last. Disinfect your hands as well as your feet and clothes, if necessary. In the case of Anthurium this can imply working with one knife per bed.

Looking for diseases

Looking for diseases and clearing away diseased plants entails many risks for further spread because plants are often dragged through the greenhouse:

- Start looking for diseases ALWAYS from ‘young’ and ’ clean’ to ‘old’ and ‘dirty/infected’.

Apply the barrier method here:

- Put diseased plants promptly in a plastic bag which should be closed immediately. Do not leave diseased plants on the path;

- Do not transport the plants above the tables but under the tables and take the diseased plants directly to a container outside;

- Hose down the direct surroundings of the diseased plants just after removing them with a suitable disinfectant like JET-5 or hydrogen peroxide in the prescribed concentration.

By applying the above measures, the risk of infection will be reduced considerably.

This article was written in collaboration with Bureau IMAC. If you require more information or additional advice, please contact Bureau IMAC.

This article is part of the Anthurinfo February 2016 – Please find all articles here.