A very dangerous disease caused by the bacterium Xanthomonas (X) can occur in Anthurium. It usually involves the bacterium Xanthomonas phaseoli pv. Dieffenbachiae (Xpd). Synonyms are X. axonopodis pv. Dieffenbachiae and X. campestris pv. Dieffenbachiae. The Xanthomonas, which is harmful to Anthurium, can occur in many different strains (types). There are mild variants where only a limited part of the range gets affected, but there are also aggressive types that spread widely and quickly. It can be latently present (without symptoms) in the plant and strike under favourable conditions. The bacteria can enter the Anthurium plant through wounds in leaves or stems and through the plant’s natural openings, such as stomata and hydathodes (guttation openings).

Optimal conditions

Warm and wet conditions in particular allow the disease to spread very quickly. The bacteria multiply by division, allowing large numbers to develop in a very short time. In addition, if water falls directly on the crop and leaf damage occurs, the bacteria can easily enter the plant. If crop humidification is used, the bacteria can be easily transferred to healthy plants via water. Xanthomonas can also be easily transferred via drainage water. In addition, the bacteria can easily be spread by people working in the crop. It is not airborne. Plants, which are stressed for any reason, appear to be especially susceptible to infection by Xanthomonas.

Damage as a result of Xanthomonas

In this article, we discuss different aspects in three parts:

- Preventive measures

- Curative measures

- Starting a new crop after infection

Take preventive measures to prevent Xanthomonas on the farm

Below, we have listed the measures to keep Xanthomonas out:

- Agree with your supplier on hygiene measures, controls and clean packaging. The disease can be transmitted very easily via cuttings or heads, for example. In a visually healthy plant, the bacteria can still be present.

- Before entering your premises, visitors should wash and disinfect their hands.

- The shed should be considered a dirty space. This is where carts, packaging, means of transport, pets and (external) people come in without adequate control to ensure proper hygiene.

- When entering the greenhouse, hygiene practices must be complied with:

– Make sure overalls are present and visitors wear them;

– It is important that footwear can be disinfected and it is even better to use shoe covers;

– Employees must change into company clothing at the farm;

– Upon entering the greenhouse, disinfect hands and feet before starting work;

– Pets do not belong in the greenhouse;

– For cut flower culture, work per bed with at least 1 separate blade that can be kept in a sleeve at the front of the pad.

Separate blade per bed

- Prevent Anthurium-related plants such as Aglaonema, Philondendron, Caladium, Dieffenbachia, Spathiphyllum and other Araceae from standing near the Anthuriums or coming into contact with your Anthuriums through (drain) water. The disease may be latently present in these types of plants without any symptoms. In this case, they can transmit the disease to Anthurium.

- Never place Anthurium plants from external sources in your farm.

- Ensure drainage water disinfection by heating (minimum 30 sec at 90 ºC ) or UV (min. dose of 100mJ/cm2).

- Clean silos thoroughly at least once a year.

- Use H2O2 to keep pipes and silos clean of organic deposits.

- Avoid water flows from outside (neighbours) entering the greenhouse as well as pests.

- Make sure you and your staff are aware of images of the disease. If you have any doubts about certain symptoms, have a specialist laboratory perform a comprehensive disease investigation, not only checking for Xpd but at least the entire plant pathogenic Xanthomonas group. This is very important because there are also non-plant pathogenic Xanthomonas species.

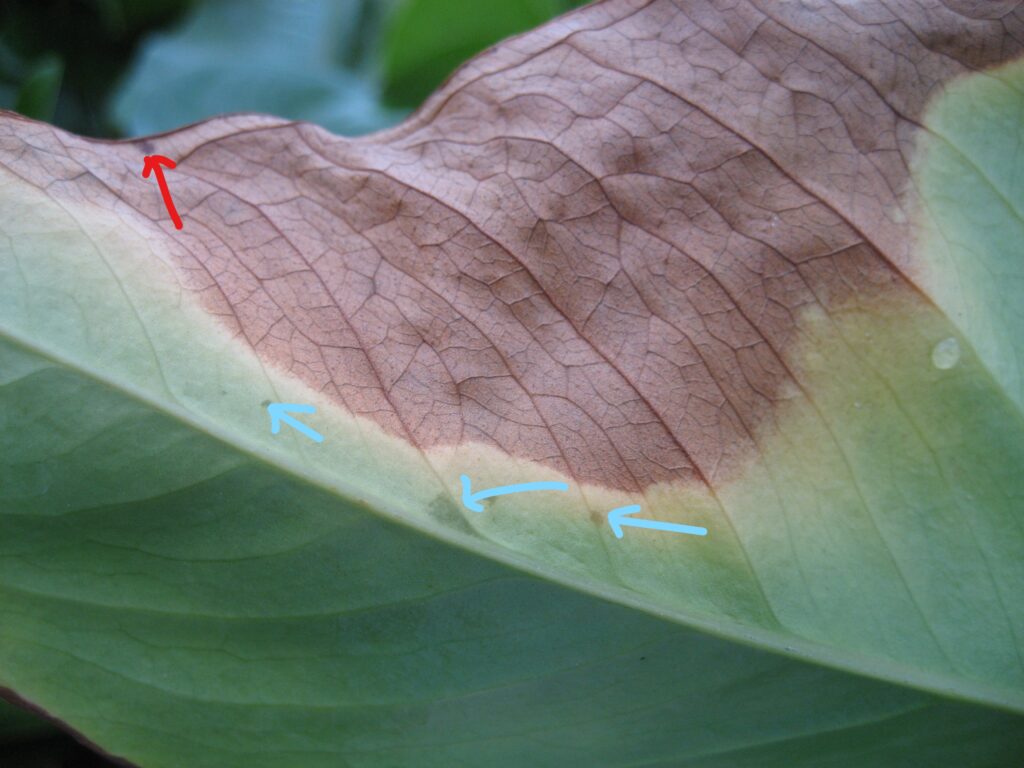

- Difficult to recognize symptom of X

- Difficult to recognize symptom of X. Blue arrow: watery spot, red arrow: black spot.

- Difficult to recognize damage images

Constantly check for remaining gaps on your farm that could break the chain of phytosanitary measures.

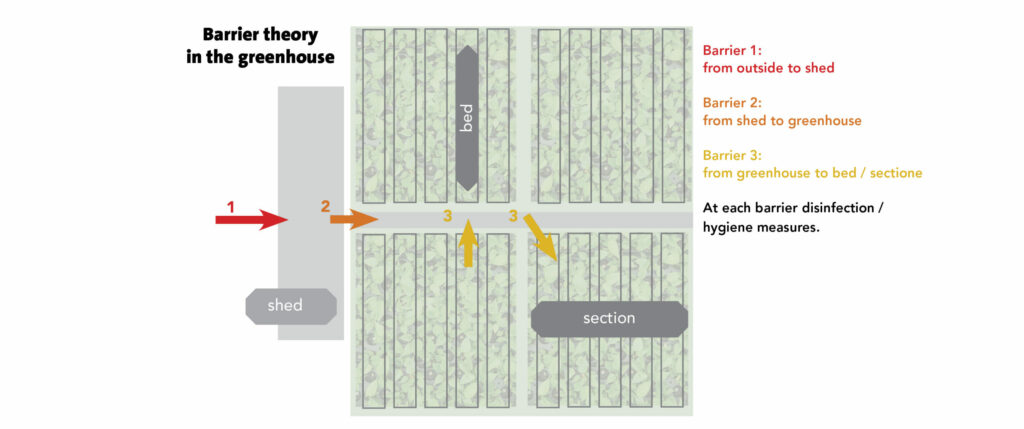

Barrier theory

- Barrier 1: from outside to shed

- Barrier 2: from shed to greenhouse

- Barrier 3: from greenhouse to bed/ section

At each barrier disinfection/ hygiene measures

Curative measures to minimise the effects of any infection present

All the measures discussed earlier are still very important. Should you still fail to keep Xanthomonas out, try to limit the damage as much as possible. This can be achieved by means of the following measures and rules:

* Work should always be done from a clean to an infected plot;

* The infected plot (or plots) should be compartmentalised. One way to do this is to mount a film to the top of the screen. The compartments should be treated as separate sections, each with its own hygiene measures.

* Scout for diseased plants at least weekly and make sure your employees are well aware of disease symptoms.

* Any infected plants should be removed from the bed in a sealed plastic bag. Plants in the immediate area should also be removed and the substrate disposed of. Anything removed should be cleared from the premises as soon as possible.

Work

Only perform work in a dry crop, i.e. never early in the morning. Through clothing, the bacteria can easily be spread over long distances.

Separated water flows

Drainage water from infected sections should preferably not be reused to minimise the risk of re-infection.

Climate

The bacteria spread easily via moisture. Air humidity promoting measures that wet the crop should no longer be used (e.g. Lego sprinklers) or only to a level where stress is prevented.

- Proper climate control should ensure that the crop remains as dry as possible. Guttering of plants should be avoided as much as possible. Heating in the morning to get the crop dry is highly recommended. Keep the root temperature below plant temperature to reduce root pressure and guttering.

- Plants that do not grow well are especially susceptible to the bacteria. Therefore, avoid extreme climate conditions and high temperatures. At 30°C, the bacteria can multiply optimally, while Anthurium can then easily become stressed.

Guttation

Bemesting

Glutamine vormt een belangrijke voedingsbron voor de bacterie en komt via het gutteren van de planten vrij. Er wordt minder glutamine door de plant gemaakt als het ammonium en nitraat stikstof zo laag mogelijk worden gehouden. Ammoniumnitraat moet uit het voedingsschema worden weggelaten en bij voorkeur moet vloeibare kalksalpeter gebruikt worden.

Control

Control of the bacteria is not possible. In the past, development could be inhibited with antibiotics (Phytostrep), copper-based agents (the bacteria do develop resistance quickly and the agents are often phytotoxic). Today, however, these agents are banned from use in horticulture.

But there are plant resistance products that are used in practice such as:

Please contact the Plantosys specialists : https://www.plantosys.com/nl/

Crop Protection

For regular (chemical) crop protection, switch to using space treatment methods, such as Fog or LVM (Low Volume Method). Normal spraying involves wetting the crop which greatly contributes to the spread of the bacteria.

Wet crop

Cut flower culture:

To prevent spread from one plant to another through the wounds made during leaf and flower cutting, the blades should be disinfected after several operations. As this becomes more refined, the chances of further spread using the blade are significantly reduced. Disinfecting after every operation is preferable, but not always feasible. Disinfection can be done with alcohol (85%), chlorine or “Menno florades” (available at Brinkman). It is best to use at least 5 blades, so that when using one blade, the other can be left in the desinfectant for a while.

Use of sprinkler system

With overhead watering (pot culture), the chance of spreading the bacteria is enormous. In cut flower culture, this applies to the use of the sprinkler system on the cultivation beds. If there is no other way, it is recommended to include stabilised H2O2 in the last part of the irrigation session. This can help reduce bacterial spread. Doses of up to 100ppm are used in practice. Prolonged and frequent use of peroxide can damage the wax layer of the crop.

Starting a new crop after infection

Should you be affected by Xanthomonas and start a new crop in part of the greenhouse after some time, efforts will also be made to prevent a possible new infection. What is the best way to proceed? Below you will find an overview of the measures and information:

- Shield the other departments from moisture, dust and materials lying around during cleaning.

- Remove all organic material present in the infected section (including weeds, old leaves and organic substrates).

- Disinfection of surfaces, materials, greenhouse stands, concrete, etc. is only useful if it is previously cleared of organic deposits. Disinfectants are only effective on clean surfaces!

- Disinfection in an empty greenhouse is possible with Formalin. Beware of damage to adjacent crops. Sprinkler systems can also be put in acid for 1 day and base for 1 day, then rinse well. For acid, take 1 litre of nitric acid (HNO3; 38%) in 30 litres of water and for base 1 kg of potash (KOH, 34%) in 30 litres of water. Sprinkler systems should be free of root and plant debris and excessive algae deposits at all times.

- Replace the current cultivation system with new materials. If reuse does take place, decontaminate what remains as thoroughly as possible. Never reuse ground cover.

- If the sprinkler systems are reused, flush them well and disinfect them properly on the outside as well.

- After clearing, everything should be disinfected, including greenhouse stands and paths.

- If possible, leave the greenhouse empty for at least 6 weeks before starting another crop.

- The new section is considered a separate area, meaning that all preventive hygiene measures apply before entering this section.

- Never reuse drip and drain lines, they are difficult to disinfect

- Get advice from a specialised agency on the right approach to cleaning your greenhouse.

If the contamination affected the entire farm, then the above measures obviously apply to the entire farm.

IT IS ONLY WITH PROPER HYGIENE MEASURES THAT THE PROBLEM CAN BE CONTAINED!

| Product | Authorisation number | Active ingredients | Dosage | Minimum application time | Observations |

| Menno ter Forte | 9308 N | didecyl dimethyl ammonium chloride | 0.4% | 5 min | Not effective on contact with soaps |

| Menno Florades | 12784N | benzoic acid | 1% | 5 min | |

| Jet 5 | 12134N | peracetic acid, hydrogen peroxide | 2% | 5 min | Corrosive |

| VirkonS | 13676N | pentakalium-bis(peroxymonosulphate)-bis(sulphate) | 1% | 10 min | Pink dye indicator |

| Hyperclean X | 14750N | sodium hypochlorite | 1% | 5 min | Corrosive |

| SYN-Formalin | 13525N | formaldehyde | 2% | 24 hours | Spraying or fogging. Fumigant action. To be carried out by a specialised company |

Disinfectants to kill Xanthomonas on materials and surfaces (copy image content)

| Product | Dosage | Active against/on | Remarks |

| Alkaline soaps | According to label | Organic material | pH higher than 10 |

| Sodium hypochlorite | 100-200 ppm | Green deposit, biofilm | Corrosive |

| Hydrogen peroxide | 1% | Green deposit, biofilm | Corrosive |

| Nitric acid | 3% | Lime in/on drippers and pipes | Caustic |

| Caustic potash | 1-2% | Footwear | Caustic |

| Alcohol gels | 70-80% alcohol | Hands | Works and dries quickly |

| Sterilium | 75% iso-propanol | Hands | Skin-friendly |

Cleaning agents, which have a disinfecting side effect (copy image content)

For more information, contact André Lont, Crop specialist Anthurium.

Email: al@anthura.nl